The

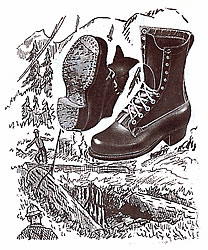

Dayton Legend – Dayton Boots Est. 1946

At

Dayton, we're proud to say that we're Canadian owned

and operated. We're proud of the fact that after 58

years our handcrafted boots are still being made in

our factory at 2250 East Hastings Street in Vancouver,

British Columbia. We're proud of our roots deep in the

heart of "East Van". And even as the Dayton Legend grows

and demand for Dayton Boots spreads around the world,

we will always remain the best boots that are "Made

in Canada". At

Dayton, we're proud to say that we're Canadian owned

and operated. We're proud of the fact that after 58

years our handcrafted boots are still being made in

our factory at 2250 East Hastings Street in Vancouver,

British Columbia. We're proud of our roots deep in the

heart of "East Van". And even as the Dayton Legend grows

and demand for Dayton Boots spreads around the world,

we will always remain the best boots that are "Made

in Canada".

Whether Dayton boots end up on the feet of a logger

or a lineman, a biker or a rock star, a soccer mom or

a super-model, every pair is made with the same attention

to detail as they have been for nearly six decades.

Every pair of Daytons is made with the same exacting

care and attention to detail that established Dayton

as the industry standard more than half a century ago.

Dayton

uses two types of footwear construction -- Nailed Construction

is an old-style, hand-nailed, heavy boot and Goodyear

Welt Construction is a Stitch-Down/Leather Welt style

of manufacturing for lighter weight Boots. The difference

is in the details. Dayton

uses two types of footwear construction -- Nailed Construction

is an old-style, hand-nailed, heavy boot and Goodyear

Welt Construction is a Stitch-Down/Leather Welt style

of manufacturing for lighter weight Boots. The difference

is in the details.

As the saying goes, once you’ve worn Daytons,

you can never go back. It’s Daytons or nothing.

No detail is overlooked, from selecting the best full-grained

premium grade hides available to using rust proof brass

nails and stainless steel fittings and the strongest

Irish linen stitching on the market. All Dayton Boots

have non-corrosive heavy steel shanks and full leather

insoles for superior foot support, comfort and durability.

'Comfort,

Quality and Durability' are built into every pair of

hand-made Daytons. Each pair is made using the highest

quality materials, with careful inspection and quality

control at every stage of construction. That's why Daytons

have a reputation for being the best-built boots in

the world. 'Comfort,

Quality and Durability' are built into every pair of

hand-made Daytons. Each pair is made using the highest

quality materials, with careful inspection and quality

control at every stage of construction. That's why Daytons

have a reputation for being the best-built boots in

the world.

In the beginning, the Dayton Shoe Co. was nothing more

than a rather unusual 'hobby' to C.H. (Charlie) Wohlford.

Wohlford, a man-about-town and club manager at The Lumberrnan’s

Social Club at 64 East Hastings, was well known to BC

loggers because he had worked for years as a troubleshooter

for the Holt Caterpillar Tractor Company up and down

the logging camps of the Pacific Northwest.

During the Second World War loggers were having difficulty

getting their boots properly repaired, something they

often complained about while enjoying Charlie’s

hospitality at the Lumberman’s Social Club. At

a bull session with a few loggers, Charlie said he would

fix all of the loggers' boots. After that fateful evening,

when Charlie wasn't pouring whiskey, he was tinkered

with the logging boots of his patrons. The biggest complaints

were that the caulks were kicking out and that the boots

weren’t water-resistant enough. Charlie repaired

the boots himself, driving new caulks into the soles

and experimenting with a veritable witch’s brew

of oils and waxes in an effort to make the boots more

water-resistant. Later, when the loggers came back into

town, they claimed that the boots that Charlie repaired

were holding up much better than when the boots were

brand new! And in the process Charlie came up with the

proprietary recipe for OK Oil Watertight Compound that

Dayton still uses to this day.

That

started it. The loggers kept pestering Wohlford to make

them a better logging boot. “Make us some better

boots, Charlie!” One evening, in the back room

of the Lumberman’s Social Club, a group of loggers,

accompanied by a case of whiskey, finally persuaded

Charlie to make boots for them. But first the boots

had to have a name. They decided that they couldn't

call them 'Wohlford Boots' because the name was too

hard to pronounce, especially after a few drinks. But

everyone could say 'Day', as in ‘Good Day’,

and that fateful evening the "Dayton" brand name was

born. That

started it. The loggers kept pestering Wohlford to make

them a better logging boot. “Make us some better

boots, Charlie!” One evening, in the back room

of the Lumberman’s Social Club, a group of loggers,

accompanied by a case of whiskey, finally persuaded

Charlie to make boots for them. But first the boots

had to have a name. They decided that they couldn't

call them 'Wohlford Boots' because the name was too

hard to pronounce, especially after a few drinks. But

everyone could say 'Day', as in ‘Good Day’,

and that fateful evening the "Dayton" brand name was

born.

In the winter of 1946 the Dayton Shoe Co. started making

boots. Working at the club and trying to get the factory

started began to take its toll on Charlie’s health,

so his son Wayne Wohlford was asked to join the firm

in March 1947 as the General Manager. Young Wohlford

rolled up his sleeves and went to work. He had to learn

the footwear business from the ground up. Coming up

with a few ideas of his own that Wayne learned from

a stint with the Boeing Aircraft Company, the factory

was enlarged and production set up.

The first Dayton Logger Boots, the Dayton “64”

hit the market in May of 1947 and were an immediate

success. Charlie always claimed that 64 was his favorite

number, no doubt in part because of his fond memories

associated with fixing the logging boots of his old

patrons at 64 East Hastings. Within no time at all,

Daytons became known as “the Logger’s choice”.

Dayton soon became the brand name for boots and the

industry standard for loggers in the woods, men on tough

construction and utility jobs, rough-necks in the oil

patch, on the docks with longshoreman, as well as with

both fire and police forces - anywhere a rugged, durable,

comfortable boot was required.

It

was the policy of Dayton Boots and Charlie Wohlford

to use the best of everything. The best number one leathers

available, the best imported boot caulks, brass nails,

etc. "Buy the best materials, make it with skilled shoemakers

and you will have a first class product", said Charlie.

Wohlford insisted on the highest standards of quality.

And Charlie was never satisfied to rest on his laurels.

He continually searched for ways and innovations to

make Dayton boots better, regardless of the cost. Dayton

has carried through this philosophy to the present day. It

was the policy of Dayton Boots and Charlie Wohlford

to use the best of everything. The best number one leathers

available, the best imported boot caulks, brass nails,

etc. "Buy the best materials, make it with skilled shoemakers

and you will have a first class product", said Charlie.

Wohlford insisted on the highest standards of quality.

And Charlie was never satisfied to rest on his laurels.

He continually searched for ways and innovations to

make Dayton boots better, regardless of the cost. Dayton

has carried through this philosophy to the present day.

The company continued to expand and moved into the present

factory in 1949. Additional styles were regularly added

to the Dayton line during the fifties and sixties, including

Daytons famous 'Western Boots'. In the seventies, Dayton

purchased the rights to manufacture the Pierre Paris

& Sons (established in 1907) and Leckie Boots (established

in 1852) lines, two former rival boot manufacturers.

In the early 1960's, Dayton added the Goodyear welt

method of boot construction to its already famous hand-nailed

line of products. This process allowed Dayton to diversify

into Western, Service and lighter footwear that still

demonstrated Dayton's high standard of quality and durability.

The first pairs of Dayton Western boots appeared in

1962. That year, Charles ‘Chunky’ Woodward,

scion to the Woodward’s store fortune and owner

of one of North America’s largest cattle ranches

asked Dayton to create a more comfortable and durable

boot for his cowboys. Dayton's Western boots were the

first to eliminate the inside seam and feature outside

seams only, to reduce chafing on the legs of the riders

and working cowhands who wore the boots. It didn't take

long for motorcyclists to recognize the wisdom of this

innovation. When Dayton customers started attaching

old tire treads to the bottoms of their boots to create

a great motorcycle boot, Dayton responded by manufacturing

the Black Beauty double-soled motorcycle boot.

Coinciding with the advent of better rubber soles, Dayton

designed and commenced production of the "Black Beauty"

double-soled motorcycle boot in 1965. This boot continues

to be one of Dayton's most popular boot lines. The "Black

Beauty" is now revered by bikers everywhere and is much

sought after in Japan and Europe, which is a testament

to the boot's international appeal. In 1978, Dayton

introduced "The Classic", a double-soled nailed-construction

engineer style boot which has since become a favorite

with motorcyclists all over the world.

During

the eighties and nineties, Dayton aggressively expanded

its "Motorcycle Boot" line and responded to the demands

of its customers by the addition of ladies sizes. The

tremendous response to Dayton's motorcycle boots led

the company to begin participating in motorcycle trade

shows and rallies throughout North America. Stops on

the tour included Daytona Bike Week, the Sturgis Rally

and Races (where Dayton has been a fixture since 1990),

The Laughlin River Run and Reno Street Vibrations, just

to name a few. During

the eighties and nineties, Dayton aggressively expanded

its "Motorcycle Boot" line and responded to the demands

of its customers by the addition of ladies sizes. The

tremendous response to Dayton's motorcycle boots led

the company to begin participating in motorcycle trade

shows and rallies throughout North America. Stops on

the tour included Daytona Bike Week, the Sturgis Rally

and Races (where Dayton has been a fixture since 1990),

The Laughlin River Run and Reno Street Vibrations, just

to name a few.

Dayton wearers are among the world’s most dedicated

customers, the boots inspiring a cult-like loyalty.

People have been married in their Daytons and buried

in their Daytons. Others have bequeathed their boots

back to the company in their wills. Fan mail sent from

every corner of the globe piles up at the factory, many

of them testimonials to the toughness and durability

of the owner’s Daytons. A biker from West Virginia

wrote “I wore my Daytons on a 12,000 mile ride

and they’re still in great shape. The other guys

were pouring water out of their boots while my feet

satyed dry.” An Alberta customer wrote to thank

the staff for rebuilding his 20 year-old Daytons, and

to say how sorry he was that he’d never get another

chance to buy a new pair; he’s in his sixties

and he expects to be buried in the pair he bought in

his forties. Other stories tell glowing reports of the

boots’ ability to withstand nearly unbelievable

punishment in all manner of accidents and emerge nearly

unscathed, their owner’s feet safe and sound inside.

By

the 1990's, the reputation of Vancouver's very own homegrown

boots had spread far and wide. They were showcased at

Vancouver’s hippest boutiques and seen on the

feet of club-goers and trendsetters throughout the city.

Dayton boots have been embraced by the fashion industry,

the music world and in BC's growing film and television

industry. On film sets around town, you can find Dayton's

adorning the feet of both movie crews and movie stars,

and Dayton Boots in front of and behind the camera.

In

2001 Dayton celebrated its 55th Anniversary by continuing

to produce timeless, classic, high quality boots for

men and women. Dayton currently manufactures some 50

different styles of shoes and boots for an ever-expanding

market divided among five sectors: motorcycle boots,

fashion styles, western boots, work boots and service

boots. Dayton plans to unveil several new styles of

shoes and boots in the coming year as well as an exciting

line of Dayton-branded apparel. When in Vancouver, you

can visit the Dayton showroom at 2250 East Hastings

Street and be fitted into a new pair of boots with the

sounds of hammers and machines only a few feet away.

It's nice to know that at Dayton, some things - like

Quality and Tradition - never change.. In

2001 Dayton celebrated its 55th Anniversary by continuing

to produce timeless, classic, high quality boots for

men and women. Dayton currently manufactures some 50

different styles of shoes and boots for an ever-expanding

market divided among five sectors: motorcycle boots,

fashion styles, western boots, work boots and service

boots. Dayton plans to unveil several new styles of

shoes and boots in the coming year as well as an exciting

line of Dayton-branded apparel. When in Vancouver, you

can visit the Dayton showroom at 2250 East Hastings

Street and be fitted into a new pair of boots with the

sounds of hammers and machines only a few feet away.

It's nice to know that at Dayton, some things - like

Quality and Tradition - never change..

Dayton

Boots are made today with the same attention to detail

as they were six decades ago. Every pair of Dayton Boots

is crafted by hand with exacting care and precision

through up to 220 individual production steps. Dayton's

team of skilled shoemakers includes men and women who

have been at the company for more than 30 years -- still

working on some of the same equipment that was in use

when the factory opened in 1950. The company continues

to carry on the tradition of making sure the company's

motto of 'Comfort, Quality and Durability' lives on

in every pair.

Dayton,

surprising people since 1946.

(Source: From the old Dayton's website) |